Bridge Construction Methods

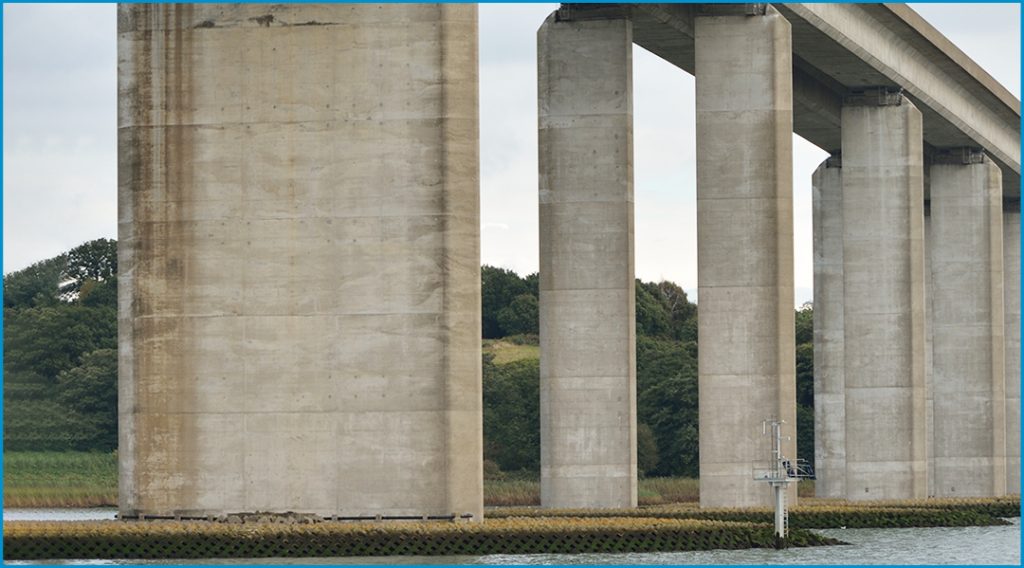

Roadways run through cities, towns, villages, forests, mountains, and deserts, spanning thousands of miles and crossing numerous obstacles via bridges. Bridges are crucial links or connectors for extending roads and can differ in their types, designs, and construction methods due to several factors. Here is an introduction to the major bridge construction methods and the factors affecting them.

Bridge construction can be a simple or complex engineering process. It is divided into three stages: foundation, substructure, and superstructure, which are interdependent. It starts with the construction of the foundation. Next comes the substructure part, and then the superstructure.

The foundation work involves comprehensive geotechnical studies of the bridge site. It is necessary to choose the type of bridge foundation, such as an open, pile, or well foundation, based on the soil stratum and the intended capacity/features of the bridge.

Similarly, the type of substructure and superstructure are selected with due diligence to ensure safety and durability with proper load-bearing design and aesthetics. As there could be challenges like difficult types of obstacles (rivers, canyons, ravines, or mountains), insufficient access to the site for the equipment, non-availability of ideal materials, traffic congestion issues, etc., different bridge construction methods should be evaluated to obtain the best possible result in a given condition.

Different bridge construction methods

Before bridge construction methods are discussed to select the most suitable one for a given condition, it’s important to learn the factors that affect the selection. Look at the list below for the principal factors:

- The length of the bridge

- The obstacle to be crossed

- The uniformity of the span lengths

- The horizontal and vertical dimensions of the bridge decks

- The characteristics of the soil strata

- The usual climatic conditions

- The cost and availability of materials

- The local labor market

- The accessibility of the site

- The working hours for construction

With the above points factoring into the selection, let’s shift our gaze to the bridge construction methods.

Precast method

Precast bridge construction refers to a concrete bridge in which precast and prestressed concrete beams, supplied to the site from remote factories, are laid on the piers and abutments, using the rubber bearings in between. Large cranes and other equipment are utilized to rest the concrete girders on the substructure as per the design.

Precast elements offer primarily two benefits: they are manufactured in the controlled environment of a plant that produces more consistently high-quality products, and secondly, since they are manufactured offsite, the overall construction time is greatly reduced, increasing project efficiency. The precast elements include:

- Precast Beams

- Precast Decks

- Precast Segmental Decks

Cast-in-situ method

For cast-in-situ or cast-in-place construction, the substructure must be completed before the construction of the superstructure. The in-situ reinforced concrete deck slab is then cast on a permanent shuttering span between the beams.

Cast-in-situ segmental construction is implemented when precast segments are too heavy to ship or site access is too limited. This situation may arise if the span gets longer to cover the wider distance.

With the flexibility of this bridge construction approach, bridges with intricate and distinctive geometric patterns can be built with ease. This strategy works well in situations when it is difficult to transfer prefabricated pieces because of their size or accessibility. Continue Reading: Cast-in-situ Bridge Construction method.

Balanced Cantilever Method

The balanced cantilever bridge construction technique can adopt precast or cast-in-situ methods. Bridge decks of lengths between 50 m and 300 m can be built using the balanced cantilever method.

Building the piers and abutments is completed before starting the deck. The bridge is then built simultaneously in both directions from each pier. This keeps each pier stable and, hence, “balanced” until the various structural components eventually come together and are joined. Prestressed tendons or bars inserted through each unit progressively bind the segments back to the piers.

Span by Span Casting method

Although this technique has seen numerous developments, it is still linked to the cantilever construction method and is thought to be one of the most cost-effective and fastest means of bridge construction.

The technique works for long bridges and viaducts with a maximum individual span of 60 meters. Starting at one abutment, decks are built constantly by assembling components for the bridge’s other end. Segments can be positioned using an assembly truss, which is the method that is used more frequently, or a temporary mast system.

Incremental Launching Method

The Incremental Launching Method (ILM) is mostly used for steel girders or continuous concrete bridges. The ILM involves constructing a part of the bridge superstructure on an abutment and then pushing the structure outward towards the first pier and then to the next pier. This way, the bridge deck is extended incrementally to span the obstacle. The ILM technique allows the construction of bridge decks longer than 250 m.

With the ILM approach, bridge construction over deep valleys, steeply sloping water crossings, or ecologically sensitive areas becomes less difficult. Compared to traditional construction, the incremental launching method (ILM) for bridge construction may have benefits such as less environmental disturbance, a more concentrated work area for superstructure assembly, and higher worker safety due to the improved construction technique.

These are the major bridge construction methods that are followed worldwide. However, engineers might adopt a combination type to accomplish a specific challenge, depending on the situation and other factors. Also, since bridge constructions are complex, time-consuming, and expensive projects, developing new techniques to create safe and enduring structures for less is a continuous endeavor of civil engineering.